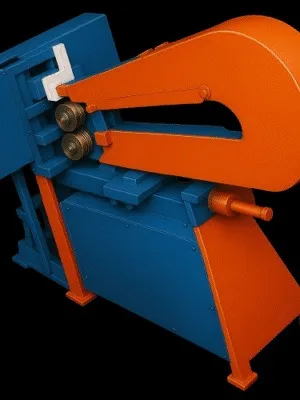

Drum Cutting Machine By Gujri – Revolutionizing Metal Drum Recycling

Drum Cutting Machine By Gujri has emerged as a groundbreaking solution in the recycling and metalworking industries. Designed and manufactured by Gujri Industries International Pvt Ltd in Ludhiana, Punjab, this machine offers an efficient, cost-effective, and safe method to process steel drums. From industrial recycling yards to fabrication workshops, users benefit from high throughput, low maintenance, and consistent precision cutting.

Drum Cutting Machine By Gujri – Key Technical Specifications

Below is a compact overview of the model’s outstanding features:

| Feature | Specification | Benefit |

|---|---|---|

| Motor Type | Single-phase / Three-phase | Versatile use in workshops and factories |

| Cutting Capacity | 40–50 drums per hour | High productivity for recycling/disposal lines |

| Drum Diameter Supported | 200–450 mm | Fits standard industrial drum sizes |

| Safety Mechanisms | Enclosed blade cover + emergency stop | Prevents operator injury during operation |

| Power Consumption | 1.5–3 kW | Energy-efficient and cost-saving operation |

| Footprint (L×W×H) | ~1.2 m × 0.8 m × 1.5 m | Compact layout for easy integration |

These core specifications show that Drum Cutting Machine By Gujri is designed for real-world, high-volume usage while ensuring operator safety and budgeting efficiency.

Drum Cutting Machine By Gujri – Why It Stands Out

What sets this machine apart is its combination of heavy-duty construction and user-friendly design. Built with high-tensile steel and precision-ground blades, it delivers burr-free cuts that streamline secondary operations. Operators find setup easy, with minimal downtime for maintenance. The inclusion of foot pedals or hand-controls gives flexibility in workshop environments.

Safety and Compliance Features

Safety is paramount in any industrial machine. Drum Cutting Machine By Gujri integrates an emergency-stop button, blade guards, and interlocked covers to ensure operator protection. Electrical systems are wired according to industrial standards (IEC), and optional overload protection preserves both machinery and personnel. These thoughtful additions make it a trusted asset in sensitive work environments.

Ideal Use Cases Across Industries

This machine serves a wide range of applications:

Recycling centers shredding used oil or chemical drums

Workshops repurposing barrels for planters, containers, or art

Hazardous waste facilities needing safe, contained cutting

Fabrication units creating custom drum-based products

Its simplicity and power make it ideal for small to midsize operations needing reliable drum processing.

Drum Cutting Machine By Gujri – Operational Efficiency

Manufactured by Gujri Industries International Pvt Ltd, this machine is designed for minimal operational cost. With a small electrical motor (1.5–3 kW) and durable mechanical systems, users save on energy and service. Routine blade sharpening and lubrication keep maintenance easy and prevent downtime. Many clients report full ROI within months due to reduced labour and faster processing.

Gujri Industries International Pvt Ltd – Efficient Shearing Solutions

Shearing machines from Gujri Industries International Pvt Ltd offer accurate, burr-free cuts essential for metal fabrication. Over-crank and under-crank mechanical shears handle typical sheet thicknesses up to 5 mm. Hydraulic NC beam shears are available for automation and high-volume production needs. Clean, precise cutting reduces scrap and enhances efficiency—key metrics for production-focused workshops.

Gujri Industries International Pvt Ltd – Specialized Drum Cutting Machinery

A standout innovation is their Single‑Phase and Three‑Phase MS Drum Cutting Machines. Capable of handling 40–50 steel drums per hour, these machines are perfect for recycling yards and repurposing workshops. Gujri Industries International Pvt Ltd designs these cutters with safety features, easy maintenance, and consistent cutting quality in mind, making them a reliable choice for sustainable operations.

Quick Installation and Training

Installation is straightforward: standard power supply, minimal alignment, and simple blade tensioning. Gujri Industries’ team ensures on-site calibration and training for operators. Guides are provided for safety, troubleshooting, and blade replacement. All-inclusive support means clients can begin production immediately after setup.

After-Sales Support and Parts

One of Gujri’s strengths lies in after-sales care. Spare parts—motors, bearings, blades—are stocked locally. Service engineers can be dispatched quickly in North India. Annual maintenance contracts include preventive checks and safety audits. If downtime does occur, replacement parts are restocked rapidly, reducing production losses.

Sustainability and Resource Efficiency

Beyond productivity, this machine helps businesses improve their environmental footprint. Drum Cutting Machine By Gujri facilitates drum reuse, repurposing, and safer recycling of hazardous material containers. It drastically reduces sharp edges and scattering debris, enabling clean metal recycling. For eco-conscious organizations, this adds value in compliance and responsibility.

Gujri Industries International Pvt Ltd – A Strategic Partner for Fabrication & Recycling Needs

To summarize, Gujri Industries International Pvt Ltd offers:

A broad machine lineup—including presses, shears, cutter, rollers, and brakes.

High-quality fabrication with strict inspection and certification.

Technologically advanced solutions with automation and CNC.

Tailored consulting, budgeting, and layout services.

Dependable after‑sales support and training.

A Strategic Investment for Workshops

In summary, Drum Cutting Machine By Gujri offers:

High throughput (40–50 drums/hour) with clean, safe cuts.

Compact design and modest power needs (1.5–3 kW).

Robust safety features and industrial compliance.

Low maintenance with accessible spare parts and local service.

Eco-friendly operations supporting reuse and recycling efforts.

Manufacturers, recyclers, and artisans seeking to process metal drums should consider Drum Cutting Machine By Gujri as a strategic investment. Its combination of performance, safety, and support from Gujri Industries International Pvt Ltd makes it a reliable tool that enhances productivity while minimizing cost and risk.

Disclaimer – As a trusted digital marketing agency, Indian Vyapaar specializes in SEO, website design, graphic design, online listing, videography, video editing, social media management, and other digital marketing services.

Overview

Features:

- Power Press Machines: C-Type, H-Type, and Cross Shaft Power Presses designed for durability and high performance.

- Shearing Machines: Over Crank, Under Crank, Hydraulic, and NC Hydraulic Shearing Machines for precise metal cutting.

- Press Brake Machines: Hydraulic and Mechanical Press Brakes suitable for various bending applications.

- Sheet Rolling Machines: Heavy Plate Rolling Machines offering excellent durability and output capability

- Drum Cutting Machines: Single and Three Phase MS Drum Cutting Machines for efficient drum processing.

- Circle Cutting Machines: Designed for accurate and efficient circle cutting operations.